Out of Outer Space to Marine Environments: The Diversity of Hermetic Sealed Connectors

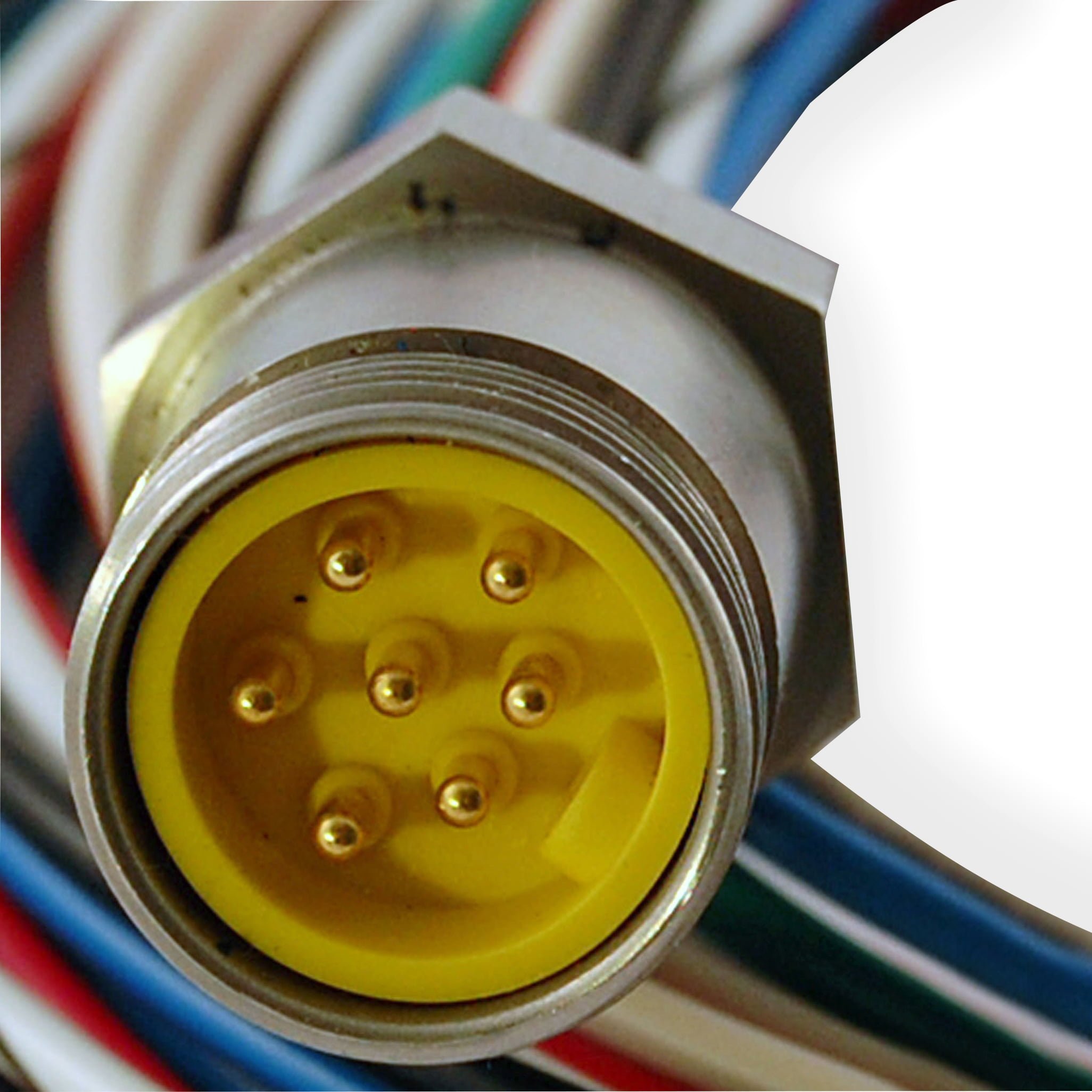

In an era where tech seamlessly bridges the gap between extreme environments, hermetically sealed interfaces have emerged as vital components in multiple industries. From the bottoms of the ocean to the vastness of space, these connectors play a crucial role in ensuring reliable electrical connections in demanding conditions. Their unique design creates a barrier against moisture, dust, and other contaminants, making them ideal for applications that demand durability and efficiency in the face of harsh elements.

Grasping how hermetic sealed connectors work provides insight into their widespread use across varied fields. By employing methods such as metal or glass seals, these connectors maintain integrity even when exposed to pressure fluctuations and temperature extremes. As industries look to enhance the strength and safety of their electrical systems, the flexibility of hermetic sealed connectors is becoming increasingly important, paving the way for more stronger designs and innovations in connection technologies.

Uses in Aerospace Engineering

Sealed hermetic connectors are essential components in aerospace usage due to their capability to protect sensitive electronics from extreme environmental factors. In the elevated and severe temperature environments of aviation vehicles and space vehicles, devices faces exposure to humidity, particulates, and corrosive substances. By offering a steady seal, these connectors maintain the integrity and longevity of electrical connections, which are crucial for the function of navigation systems, communication devices, and a variety of onboard instruments.

Moreover, the reliability of sealed connectors adds to overall flight safety. In aerospace, failure of any part can have dire implications, making it crucial that all connectors keep their performance even under the pressure of shaking, fluctuations in pressure, and thermal cycling. By using these connectors, engineers can develop systems that are both robust and effective, ultimately improving the operational reliability of aircraft and space systems.

Moreover, hermetic sealed connectors allow advancements in aerospace tech. As the field progresses towards more streamlined and lightweight designs, these connectors facilitate advanced miniaturization efforts while still delivering reliable performance. The versatility of sealed connectors enables their use in diverse applications, ranging from satellite systems to avionics systems, thus being instrumental in the advancement of contemporary aerospace tech.

Aquatic Environmental Resilience

Oceanic environments are among the some of the demanding in terms of conditions that electrical connectors must withstand. Saltwater, moisture, and thermal fluctuations can lead to oxidation and deterioration of substances. Sealed sealed connectors excel in these conditions because they are designed to provide a complete shield against moisture, salinity, and contaminants. By using advanced sealing technologies, these connectors maintain their strength and performance, even under the harshest marine conditions.

Furthermore, hermetic connectors are made from substances that are inherently resistant to the corrosive effects of saltwater. This ensures that the connectors remain functional over extended exposure to marine environments. The ability to prevent degradation not only extends the life of the equipment but also reduces the need for regular maintenance and refurbishment, which can be expensive and labor-intensive in ocean applications.

In addition to their water-tight design, hermetic sealed connectors exhibit robust performance in terms of pressure resistance. They can endure the significant pressures found at various ocean depths, making them suitable for underwater applications like submersible vehicles and underwater sensors. This durability ensures that critical electronic systems remain operational, contributing to the safety and reliability of marine operations.

Future Developments in Connectors

The prospective outlook of hermetic sealed connectors promises exciting advancements fueled by the growing demand for reliability in harsh environments. As sectors progress, there is an increasing emphasis on creating materials that can withstand extreme heat and damaging elements. Innovative composites and emerging substances will guarantee that these connector systems not only maintain their structure but also improve efficiency. This evolution will enable hermetic connectors to be applied in broader applications, from deep-sea research to space industry.

Another important trend is the incorporation of intelligent technology within hermetic sealed connector systems. As the IoT grows, connectors with built-in sensor technology and monitoring capabilities are becoming necessary. These smart connectors will allow immediate oversight of the integrity of systems, allowing proactive maintenance and reducing interruptions. The incorporation of such technologies enhances the functionality of hermetic sealed connector systems and meets the needs of contemporary uses in advanced technology industries.

Finally, eco-friendliness is emerging as a crucial driver for innovation in connector technology. As sectors focus on reducing their impact on the environment, hermetic sealed connectors will increasingly utilize recyclable substances and eco-conscious manufacturing processes. This shift not only supports eco-friendly initiatives but also drives down production costs. The creation of sustainable hermetic connector systems will guarantee that they remain relevant and sought after in an ever-changing market, providing long-lasting answers for multiple uses.